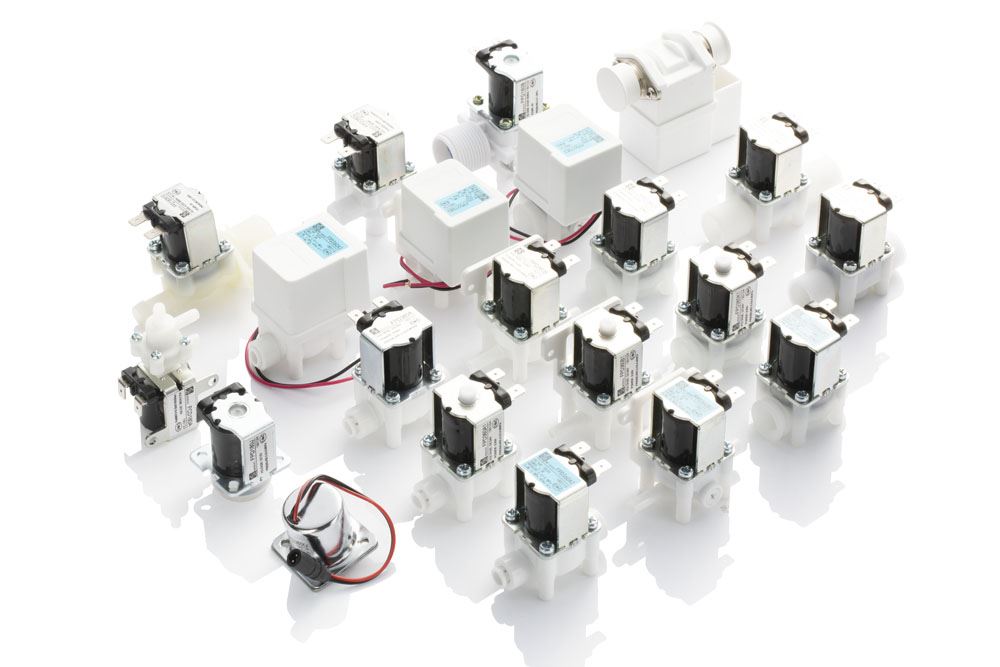

Solenoid valve is one of the commonly used valves in automatic control systems. It is inexpensive, simple to use, convenient and reliable (

It can directly accept PLC or DCS on-off control signals) and is unanimously favored by users. of course,

No matter how good things are, they have to be used properly in order to perform their functions.

Here is a brief description of the problems that need to be paid attention to in the installation, use and maintenance of solenoid valves.

1.

First check whether the solenoid valve is consistent with the selection parameters, such as power supply voltage, medium pressure, pressure difference, etc., especially

If the power supply is wrong, it will burn out the coil. The power supply voltage should meet the voltage fluctuation range of the rated voltage: AC +10%~-15%, DC +10%~-10%, usually the coil components should not be disassembled.

2. Flush the pipe before taking over the pipe to remove the metal powder and sealing material residues in the pipe, rust, etc.

Pay attention to the cleanliness of the medium. If the medium is mixed with dirt, impurities, etc., which hinder the normal operation of the solenoid valve, a filter or screen should be installed in the pipeline.

3.

Generally, the solenoid coil components of the solenoid valve should be installed vertically upwards and installed in the pipeline horizontal to the ground.

Time restrictions or working conditions must be installed on the side, which should be mentioned when ordering. Otherwise, the solenoid valve may not work properly

4. Manual shut-off valves should be installed before and after the solenoid valve, and a bypass should be provided to facilitate the maintenance of the solenoid valve in case of failure.

5.

Solenoid valves are generally directional and cannot be installed reversely. They are usually used on the valve body to indicate the flow direction of the medium, and install in the direction indicated by the →. However, it can be reversed in vacuum lines or under special circumstances.

6.

If the medium will have water hammer, you should choose a solenoid valve with waterproof hammer function or take corresponding preventive measures.

7. Try not to keep the solenoid valve energized for a long time,

This will easily reduce the service life of the coil or even burn out the coil, that is, the normally open and normally closed solenoid valves cannot be used interchangeably.

8. The solenoid valve does not work after being energized: check whether the power connection is bad → rewire and connect the connector; check the power

What brand of hydraulic solenoid valve is good

Chongqing Nishi Valve is one of the most powerful manufacturers in the southwest region, with business covering all regions of the country. Chongqing Nice Valve——http://www.cq-ns.com/Index.asp has long been committed to various fluids (...

View full text

Whether the source voltage is within the working range-→ adjust to the normal position range; check whether the coil is unsoldered → re-soldering;

The coil is short-circuited → replace the coil; Is the working pressure difference inappropriate → adjust the pressure difference → or replace a commensurate solenoid valve;

The fluid temperature is too high → replace the commensurate solenoid valve;

Impurities cause the main valve core and moving iron core of the solenoid valve to jam → clean, if the seal is damaged, replace the seal and install the filter; The viscosity of the liquid is too large,

The frequency is too high and the service life is up → replace the product.

9. The solenoid valve cannot be closed: The seal of the main spool or the iron core is damaged →replace the seal;

Whether the fluid temperature and viscosity are too high → replace the corresponding solenoid valve; impurities enter the main valve core or moving iron core of the solenoid valve → clean;

The life of the spring is reached or deformed→replace; The orifice balance hole is blocked→clean in time;

The working frequency is too high or the service life has expired → change the product or update the product.

10. Other conditions: internal leakage→check whether the seal is damaged and the spring is not properly assembled;

External leakage → loose connection or broken seal → tighten the screw or replace the seal; noise when energized → loose parts on the head,

Tighten. If the voltage fluctuation is not within the allowable range, adjust the voltage. If the suction surface of the iron core is impurity or uneven, clean or replace it in time. If you need to know more about the solenoid valve quotation, selection, pictures, parameters, please continue to pay attention to Yisel Industrial Control.

selena

selena  sales@msrelay.com

sales@msrelay.com 13968707033

13968707033

+86-577-62518811

+86-577-62518811