Electromechanical Relays and Solid State Relays

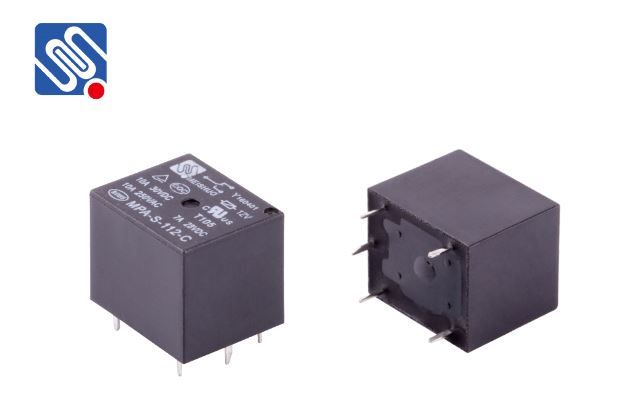

The relay can be an electromechanical relay or a solid state relay.

In an electromechanical relay (EMR), the contacts are opened or closed by magnetic force. Using solid state relays (SSR), there are no contacts, and the switch is completely electronic.

The decision to use an electromechanical relay or a solid state relay depends on the electrical requirements of the application, cost constraints, and life expectancy.

Although solid state relays have become very popular, electromechanical relays are still very common.

Many functions performed by heavy equipment require the switching functions of electromechanical relays. Solid state relays use immovable electronic devices (for example, silicon controlled rectifiers) to switch current.

These differences in the two types of relays lead to the advantages and disadvantages of each system.

Since the solid state relay does not have to energize the coil or disconnect the contacts, it requires less voltage to "open" or close the solid state relay.

Similarly, solid-state relays open and close faster because there are no moving physical parts. Although there are no contacts and moving parts, which means that the solid state relay will not arc and will not wear out, the contacts on the electromechanical relay can be replaced, and when any part fails, the entire solid state relay must be replaced.

Due to the structure of the solid state relay, there is residual resistance and/or leakage regardless of whether the switch is open or closed. The resulting small voltage drop is usually not a problem.

However, due to the relatively large distance between relays, electromechanical relays provide cleaner on or off conditions, which is a form of insulation.

selena

selena  sales@msrelay.com

sales@msrelay.com 13968707033

13968707033

+86-577-62518811

+86-577-62518811