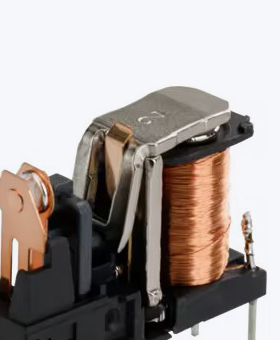

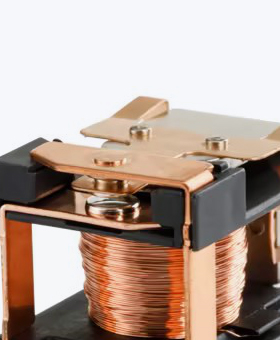

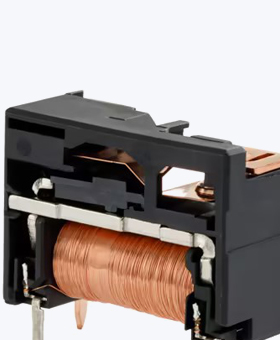

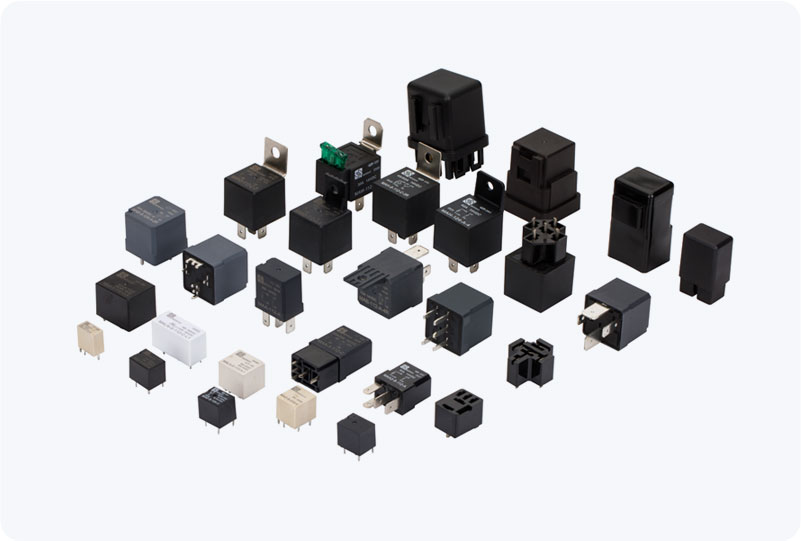

Relay is an electrical switch device that controls one circuit by using electromagnetic induction to open or close another circuit. They are widely used in various application fields, including power systems, automation, automotive, and electronic devices, providing electrical isolation and reliable switching functions, enhancing circuit safety and flexibility.

Our solution is designed specifically to address a variety of issues related to circuit control, protection, and automation, and it is applicable to a wide range of industries and application areas.

Household Appliances

Household Appliances