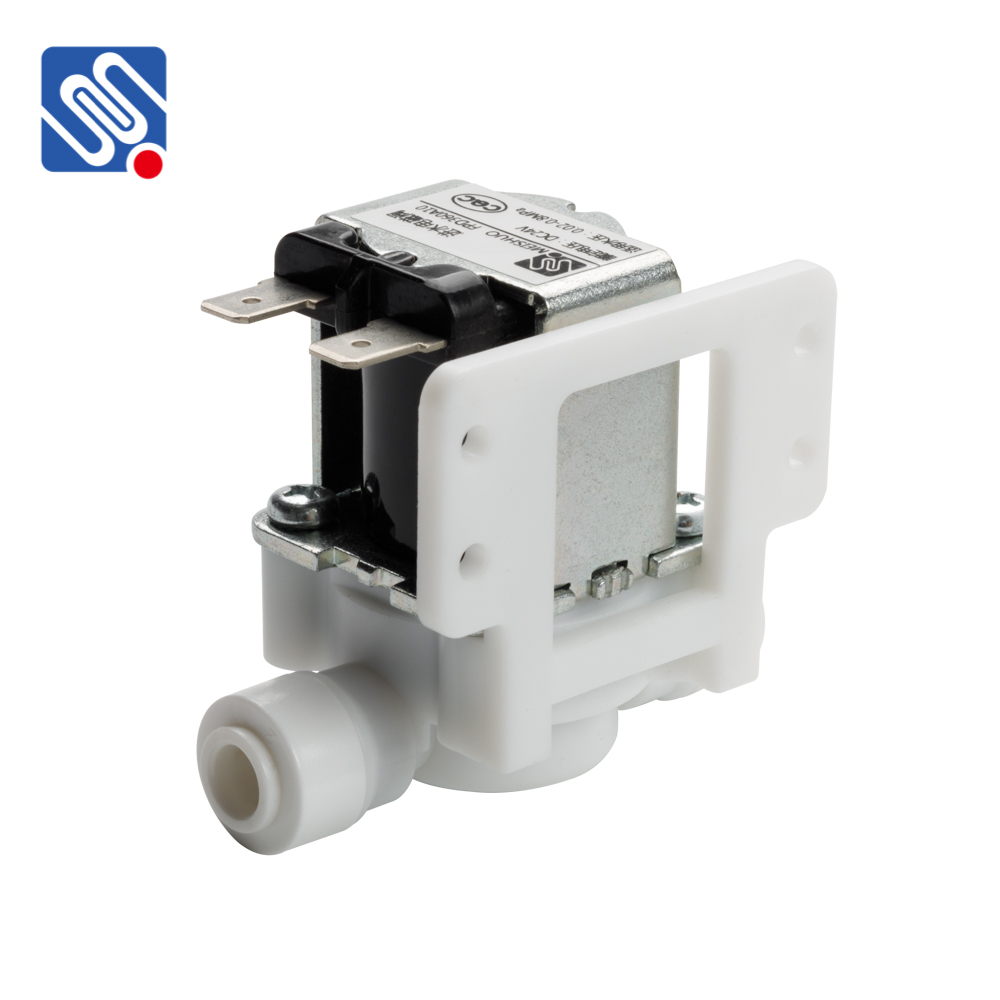

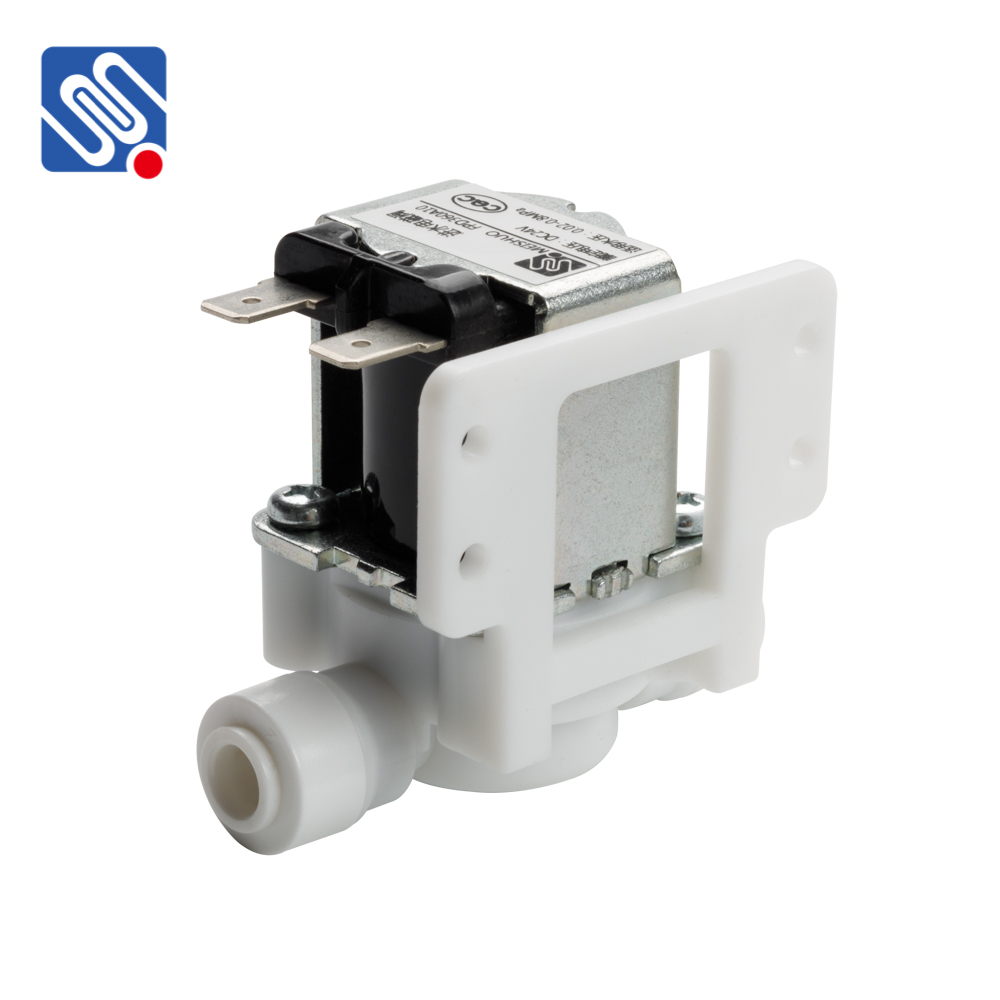

stainless steel and plastic solenoid valve: a versatile solution for modern fluid control

Release time:2025-04-27 14:09:37

In the world of fluid control, solenoid valves play a pivotal role in regulating the flow of liquids and gases. These valves are used in various industries, including manufacturing, automation, water treatment, and more. Solenoid valves operate through an electrically controlled magnetic field, which activates a plunger inside the valve, opening or closing the flow path. The materials used to construct these valves can vary depending on the application, with stainless steel and plastic being two of the most commonly used materials for solenoid valves. Both materials offer distinct advantages that make them ideal for specific environments and industries.

Stainless Steel Solenoid Valves

Stainless steel solenoid valves are known for their durability, strength, and resistance to corrosion, making them suitable for a wide range of applications, especially in harsh environments. Stainless steel is an alloy primarily made of iron, carbon, and chromium, which gives it superior resistance to rust, oxidation, and other forms of corrosion. This property makes stainless steel solenoid valves ideal for industries where fluids may be highly corrosive, such as chemical processing, food and beverage, pharmaceuticals, and oil and gas.

One of the key advantages of stainless steel solenoid valves is their high resistance to temperature variations. Stainless steel can withstand both high and low temperatures, making these valves suitable for use in extreme conditions. In addition, stainless steel solenoid valves are robust and can handle high-pressure environments, ensuring reliable performance in critical applications where failure is not an option.