flow control solenoid valve: essential component for precise fluid regulation

Release time:2025-06-28 16:59:40

Flow Control Solenoid Valves are vital components used in numerous industries for regulating the flow of fluids. These valves combine the precise control of solenoids with the functional necessity of regulating fluid flow in hydraulic, pneumatic, and other systems. By using an electromagnetic solenoid to operate a valve, they offer highly efficient and accurate control of fluid dynamics. This article will explore the construction, working principle, applications, and advantages of flow control solenoid valves, highlighting their importance in modern industrial systems.

Understanding Flow Control Solenoid Valves

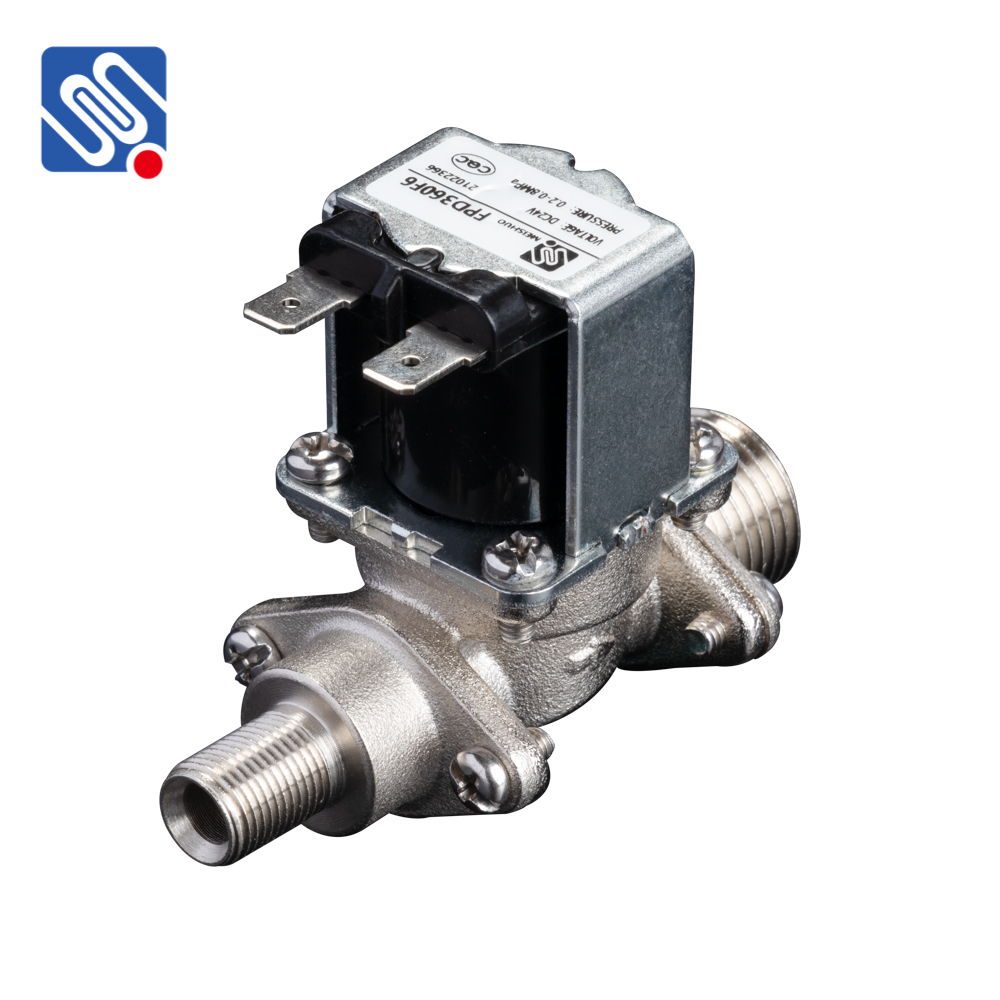

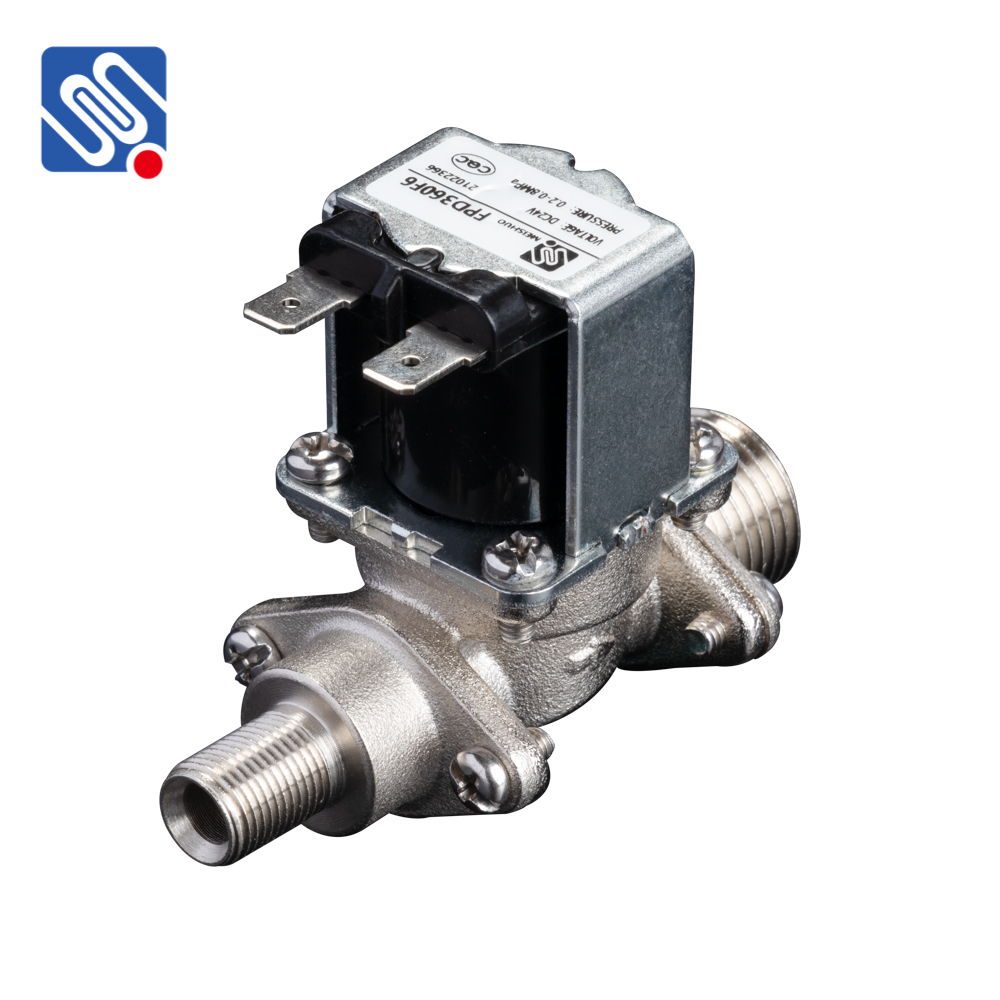

At their core, flow control solenoid valves consist of a solenoid coil, a valve body, and a spool or other mechanisms that regulate the flow of fluids. The solenoid coil, when energized, creates a magnetic field that shifts the spool or valve element, changing the path or size of the opening for the fluid to pass through. The solenoid, which is controlled by an electrical signal, provides fast and precise actuation, making these valves ideal for systems that require dynamic flow control.

The valve body is typically made from durable materials like stainless steel or brass, ensuring longevity and resistance to wear and corrosion, especially in environments with high pressure or harsh fluids. The flow control mechanism can vary depending on the specific type of valve, with options including adjustable flow settings, pressure compensation, and check valve mechanisms.