stainless steel and plastic solenoid valve: a comparative analysis

Release time:2025-06-29 10:41:46

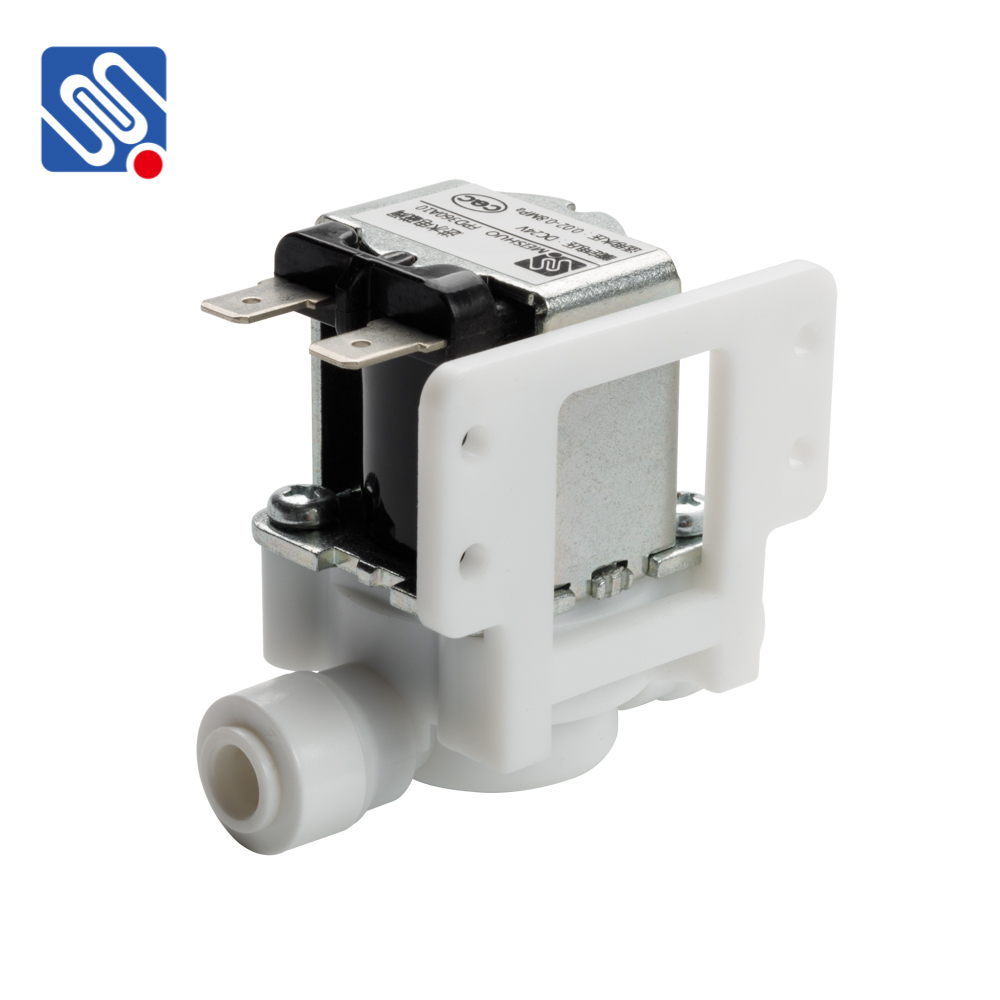

Solenoid valves are integral components in fluid control systems, regulating the flow of liquids or gases. They use an electromagnetic coil to control the valve opening and closing, providing an efficient and automated way to manage fluid dynamics. Among the many types of solenoid valves available, stainless steel and plastic solenoid valves are two of the most commonly used materials, each offering unique benefits for specific applications. This article explores the characteristics, advantages, and typical uses of both stainless steel and plastic solenoid valves.

Stainless Steel Solenoid Valves

Stainless steel solenoid valves are constructed using high-quality stainless steel, which is known for its durability, corrosion resistance, and high-strength properties. These valves are ideal for demanding environments where fluids or gases may be under high pressure or subjected to extreme temperatures.

One of the primary advantages of stainless steel solenoid valves is their resilience in harsh conditions. Stainless steel is highly resistant to corrosion, making it well-suited for environments where the fluid being controlled may be aggressive or corrosive. This includes industries such as oil and gas, chemical processing, pharmaceuticals, and food production. The robust nature of stainless steel ensures that the valve maintains its integrity and performance, even when exposed to challenging substances like acids, alkalis, and solvents.