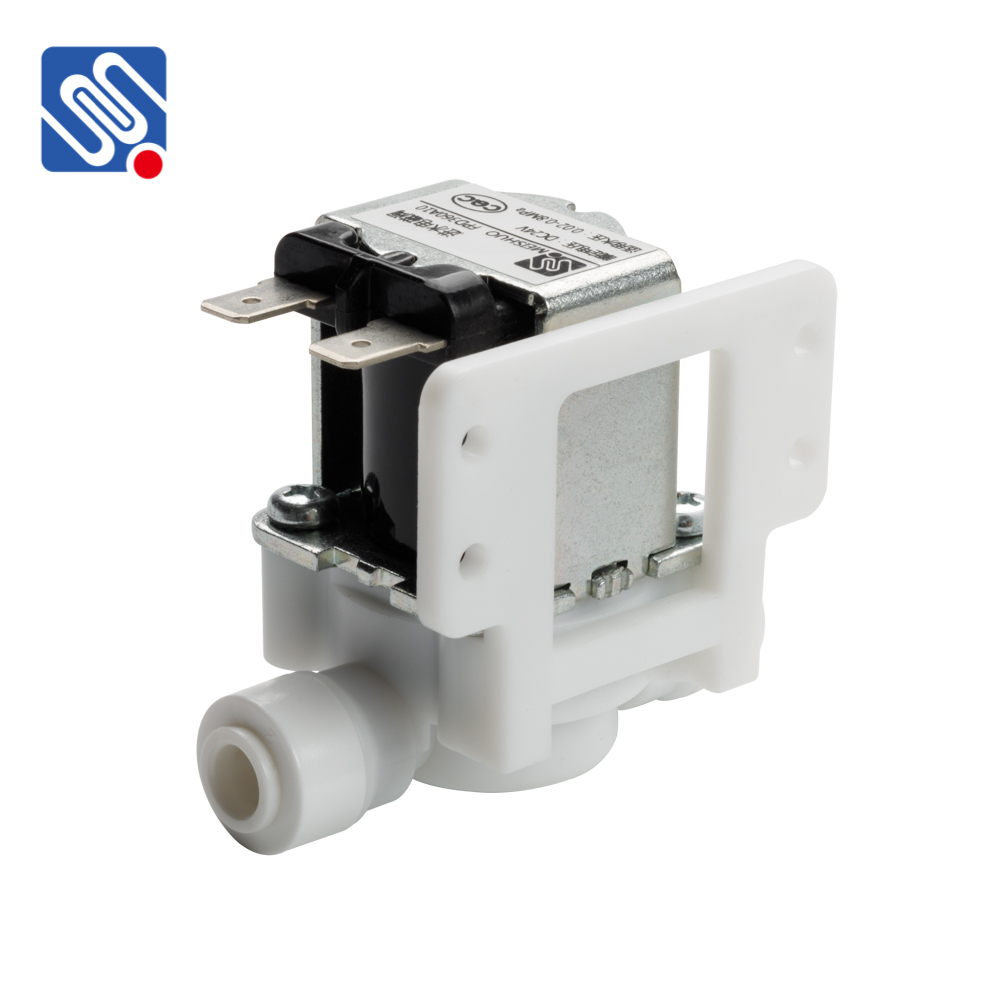

stainless steel and plastic solenoid valve: key features and applications

Release time:2025-07-04 15:15:07

Solenoid valves are electromechanically operated valves that control the flow of liquids or gases in a variety of industrial applications. They are widely used for automation purposes in systems where precise control of flow is essential. Solenoid valves are often made from various materials, including stainless steel and plastic, each of which has its unique advantages and suitable use cases. This article explores the characteristics, benefits, and applications of stainless steel and plastic solenoid valves.

What is a Solenoid Valve?

A solenoid valve operates through an electric current applied to a solenoid coil. The coil generates a magnetic field that moves a plunger within the valve, opening or closing the valve’s orifice. Solenoid valves can be classified into two categories: direct-acting and pilot-operated. Direct-acting solenoid valves use the force generated by the solenoid to directly open or close the valve, while pilot-operated valves rely on pressure differentials to control the flow.

Stainless Steel Solenoid Valves: Durability and Strength

Stainless steel solenoid valves are designed for applications that require high durability, strength, and resistance to corrosion. Stainless steel, an alloy primarily made of iron, chromium, and nickel, offers exceptional resistance to corrosion and high temperatures. This makes stainless steel solenoid valves an excellent choice for industries such as food and beverage, pharmaceutical, and chemical processing, where hygiene and material integrity are critical.