stainless steel and plastic solenoid valve: a comprehensive overview of their applications and advantages

Release time:2025-12-06 13:58:56

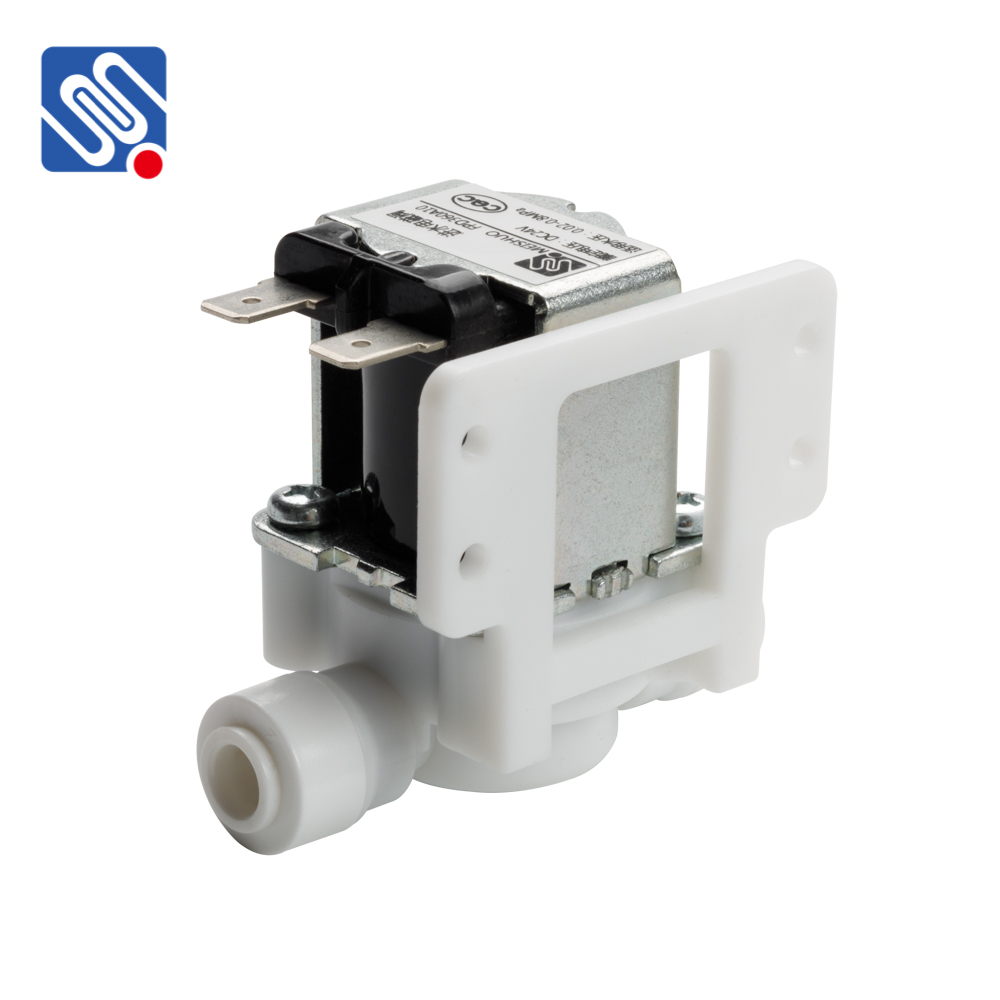

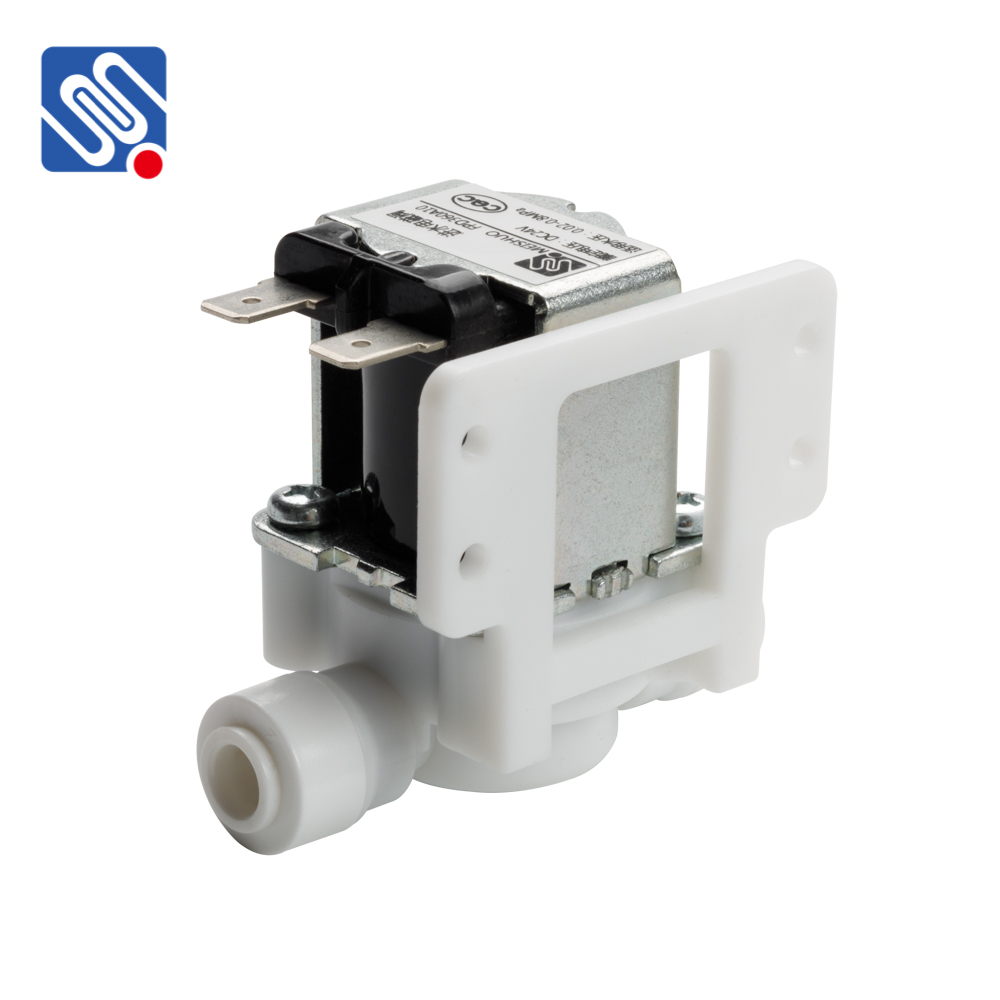

Solenoid valves are essential components used in various industries for controlling the flow of fluids and gases. These valves function using an electromagnetic mechanism, opening or closing to control the passage of substances. Two common types of solenoid valves, namely Stainless Steel Solenoid Valves and Plastic Solenoid Valves, are used widely across different sectors due to their unique material properties and advantages. In this article, we will explore the characteristics, applications, benefits, and drawbacks of both types of solenoid valves.

1. Introduction to Solenoid Valves

A solenoid valve consists of an electromagnet (solenoid) that, when energized, moves a plunger or diaphragm to either allow or block fluid flow. Solenoid valves are widely used for their efficiency and automation capabilities in a wide range of applications, from industrial processes to residential systems. The two types of solenoid valves we will discuss—stainless steel and plastic—differ mainly in the materials used for their construction, influencing their suitability for various environments.

2. Stainless Steel Solenoid Valve

Stainless Steel Solenoid Valves are made using durable and corrosion-resistant materials such as 304 and 316 stainless steel. These materials ensure the valves can handle harsh chemicals, high temperatures, and high pressures. Stainless steel valves are typically used in environments where durability and resistance to corrosive substances are paramount.