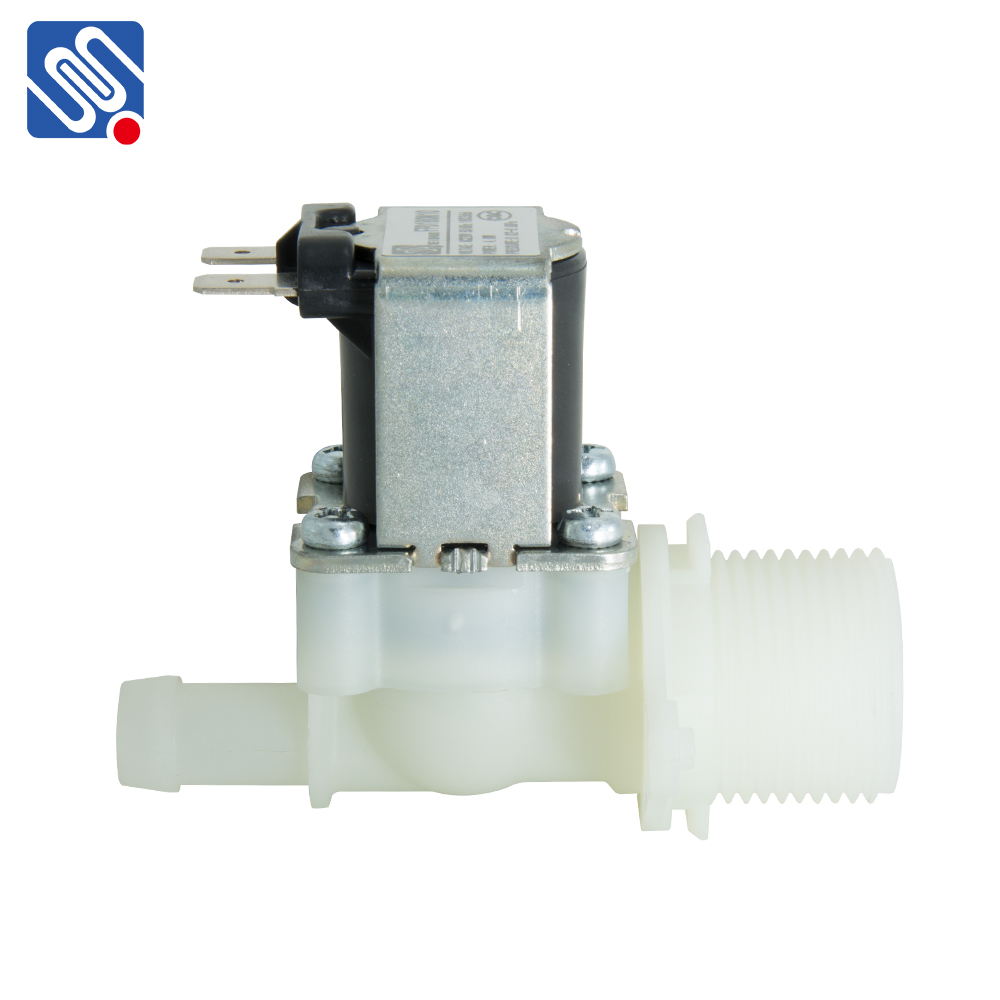

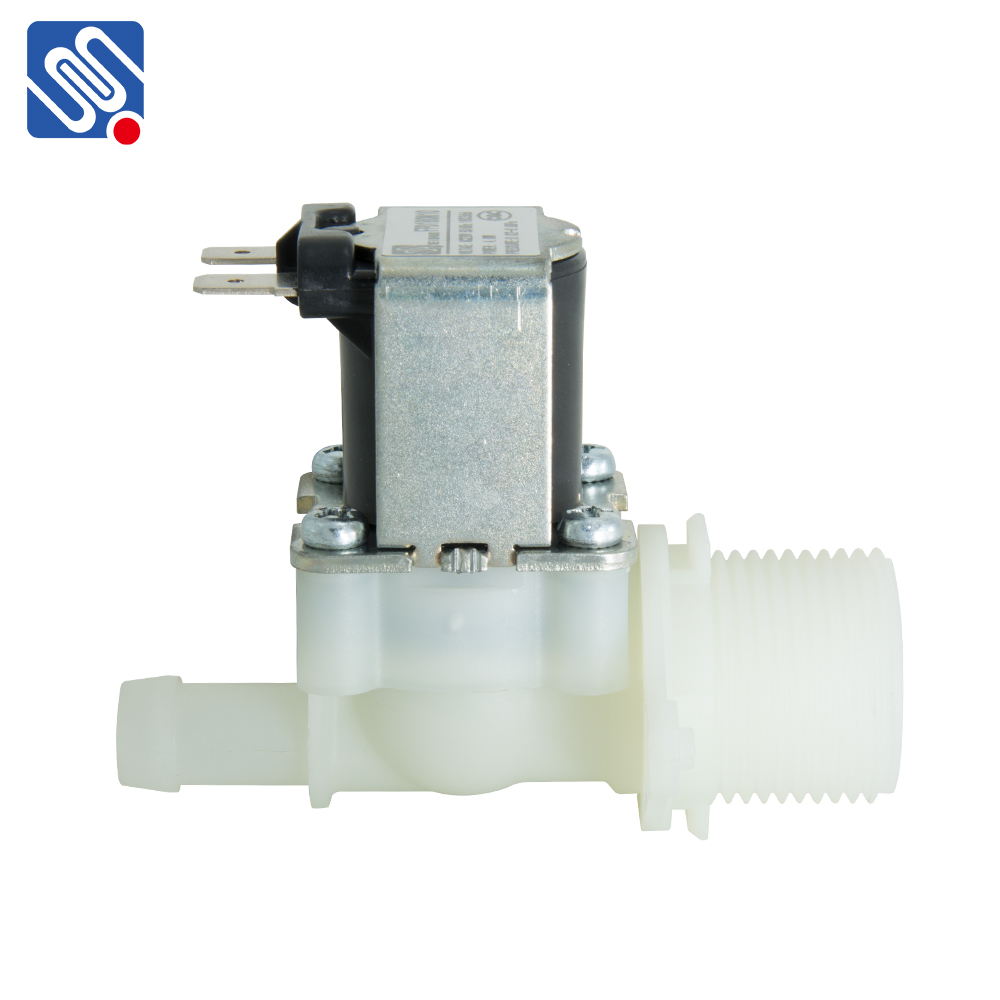

understanding the durable plastic solenoid valve: a versatile solution for fluid control

Release time:2026-01-07 22:24:56

In the ever-evolving landscape of industrial automation and fluid management, the Durable Plastic Solenoid Valve has emerged as a crucial component, vital for a myriad of applications. Known for their reliability, corrosion resistance, and lightweight construction, these solenoid valves are rapidly gaining popularity in various sectors, including water treatment, HVAC systems, agriculture, and food processing. This article delves into the characteristics, advantages, applications, and maintenance practices associated with durable plastic solenoid valves.

Characteristics of Durable Plastic Solenoid Valves

Durable Plastic Solenoid Valves are primarily constructed from engineering-grade plastics such as polypropylene and polyvinyl chloride, which offer significant resistance to corrosion and chemical exposure. This property makes them an excellent choice for applications involving aggressive fluids or in environments where metal valves would succumb to rust and wear. The internal components, including the seals and diaphragm, are often made from specialized elastomers that can withstand high temperatures and pressures.

The operation of a solenoid valve hinges on an electromagnetic coil. When an electric current flows through this coil, it generates a magnetic field that either opens or closes the valve's flow path, thereby controlling the flow of liquids or gases. This swift response time is critical in automated systems that require precision and efficiency in fluid control.